Sustainability is an important pillar for Aviko Rixona. By installing an industrial heat pump in one of its factories, the manufacturer of dried potato products has taken a major step towards halving its CO2 emissions by 2030.

At its production site in Warffum (Groningen), Aviko processes potatoes into potato granules. The granules are used as a raw material for countless products in the global snack industry. As part of Royal Cosun, an international group of companies specialising in the production of food ingredients and natural foods, Aviko Rixona has committed to the Climate Agreement. The company aims to halve its CO2 emissions by 2030. One of the measures is the purchase of a heat pump from Equans Refrigeration.

Jeroen Zwietering, the energy process engineer at Aviko Rixona, says: “To achieve the reduction target, we analysed our production processes for heat consumption and heat recovery potential. For blanching the potatoes, we heated the process water indirectly with natural gas. For re-cooling the potatoes, we used a traditional cooling system (chiller). This meant a double loss of energy, as most of the heat released during the cooling process was discharged outside, and the chiller consumed a lot of electricity. Combining this heat and cooling demand was therefore one of the possibilities. We asked Equans to design a system that would bring the energy supply and demand together, with the highest possible efficiency and for an acceptable investment. Then you quickly end up with a heat pump.”

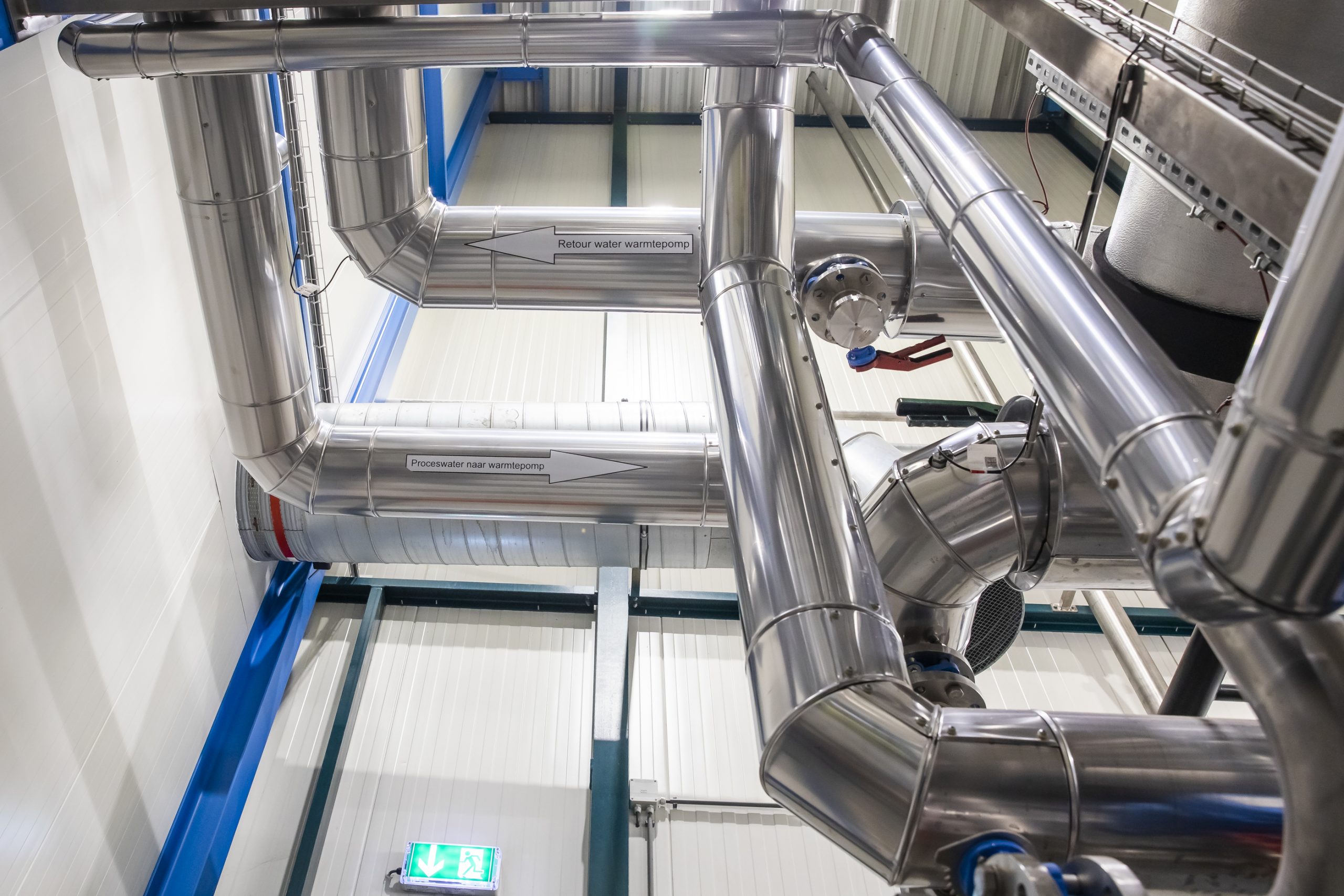

Equans started designing the installation in February 2022. Project manager Gert Boersma: “The heat pump had to meet the requirements for an SDE++ subsidy, have the shortest possible payback period and be reliable, as the granulate production runs day and night. The pump also had to fit into Aviko Rixona’s newly built machine room. The final result is a machine the size of an average living room that uses four times less energy than a traditional heating system.”

Boersma also thought about the cleanability of the system. He explains: “The water that comes out of the boiler with blanch water is contaminated. To prevent the shell-and-tube heat exchangers from clogging, the water pipes have to be cleaned several times a year. Folding covers on the heat exchanger ensure that the water pipes are easily accessible. We have also increased the diameter of the tubes in the heat exchanger to make it easier to brush them clean. The material that comes into contact with the water in the heat exchangers is made of stainless steel to prevent corrosion. An in-line filter is installed to minimise fouling. Aviko Rixona can also monitor the water supply so that they know in time when cleaning is needed.”

A big advantage for Aviko Rixona was that Equans was able to build the heat pump at its production site in Panningen. This meant that the production of granulate in Warffum could continue uninterrupted. Once built, the installation was transported by truck. When the cold and hot water pipes were connected to the heat pump and the heat pump was filled with the natural refrigerant ammonia, the installation could be commissioned in November 2022. Switching from the old system to the heat pump took just one day.

“The commissioning of the heat pump is a major milestone. We are very happy with it. Equans has responded appropriately to our requirements and the service is excellent,” says Zwietering. “With the heat pump, we achieved two goals at once. We no longer need a gas-fired boiler for blanching, and we can now heat the potatoes with a heat pump that uses heated water from the cooling process as a source. The heat pump saves us a lot of energy and gas, which is a good step towards reducing our CO2 emissions by 50%.”