Prevent malfunctions and downtime in the chemical and process industries

In the chemical and process industries, production has to run smoothly. After all, a faltering installation or downtime causes production losses, repair costs, and possibly the costs of replacing parts. Good maintenance ensures continuity, quality installations and extended lifespan.

At Equans, we aim for a long-term partnership with certified personnel, unprecedented technical knowledge and productive maintenance of refrigeration, freezer and heat pump systems. By frequently inspecting your installations, we know them inside out and exactly how they perform, how they should perform and when they need maintenance. As a result, we can accurately schedule maintenance and inspection activities. With an annual maintenance plan, you have a clear picture of the lifecycle costs in advance, i.e. the investment required for new construction or to keep your installations in perfect condition over the years.

Fast turnaround in oil, gas and chemical industry

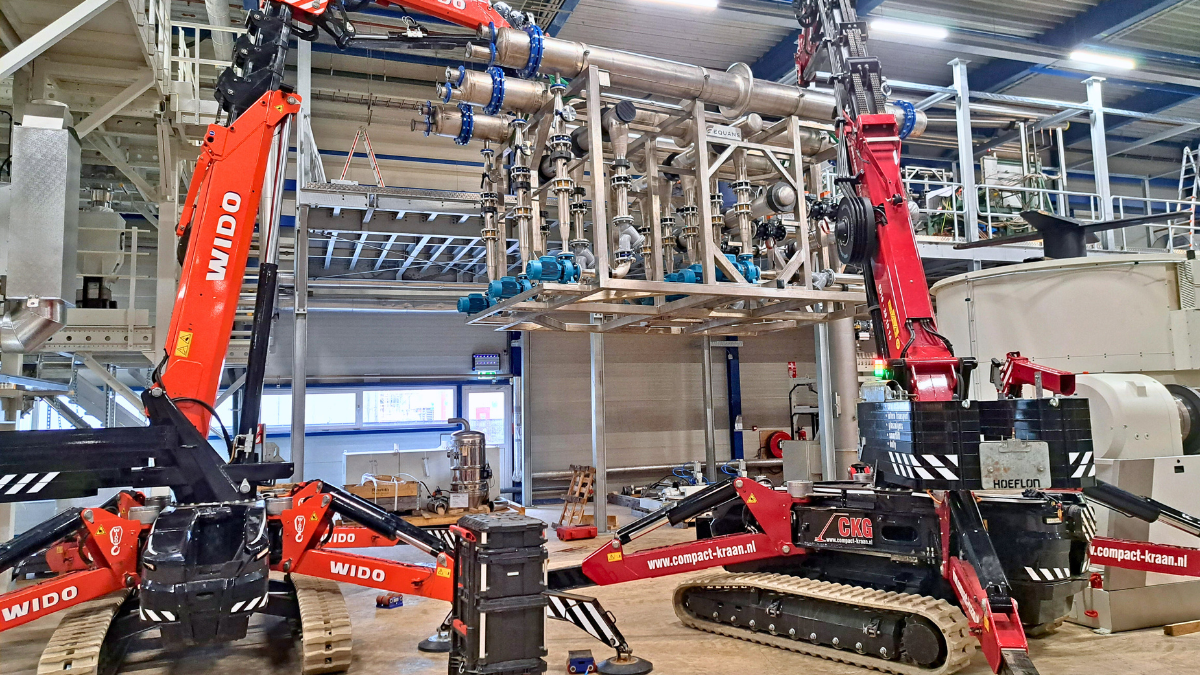

We know that production line continuity is important to your. Therefore we do our utmost to ensure that the turnaround is completed as quickly as possible. During such a turnaround, we dismantle the equipment, perform maintenance and overhaul or replace parts where necessary. For example, we clean evaporators and oil separators and overhaul compressors. We minimise downtime by completing our work quickly.

Documentation from guidelines

Project document flow is just as important in the implementation of the project. That is why we supply almost as much paper as steel during our projects. Our employees are certified in lifting operations and tightening of flanges. They know all the rules and requirements of European and US standards, including PED (2014/68/EU), Lloyds, ASME IV, EN-ISO 9606-1, ATEX and DNV. During every consultation, we discuss all planned work to avoid surprises.

Optimising energy flows and processes

Process and chemical industries are energy intensive sectors, with different heat flows, each serving a process. Did you know that there are often efficiency gains to be made within these energy flows? For example, you can improve the production process by adding an industrial heat pump which produces energy in a sustainable and energy-efficient way.

Using excess heat or heat from an industrial process to be used in other processes is called heat integration. By cleverly integrating heat flows you will better meet your production heat demand. For example, heat from a process or ambient water can be used to heat a process stream. Heat integration makes your plant more sustainable, more efficient and more future-proof. This not only saves energy but also prevents energy waste and reduces carbon emissions.