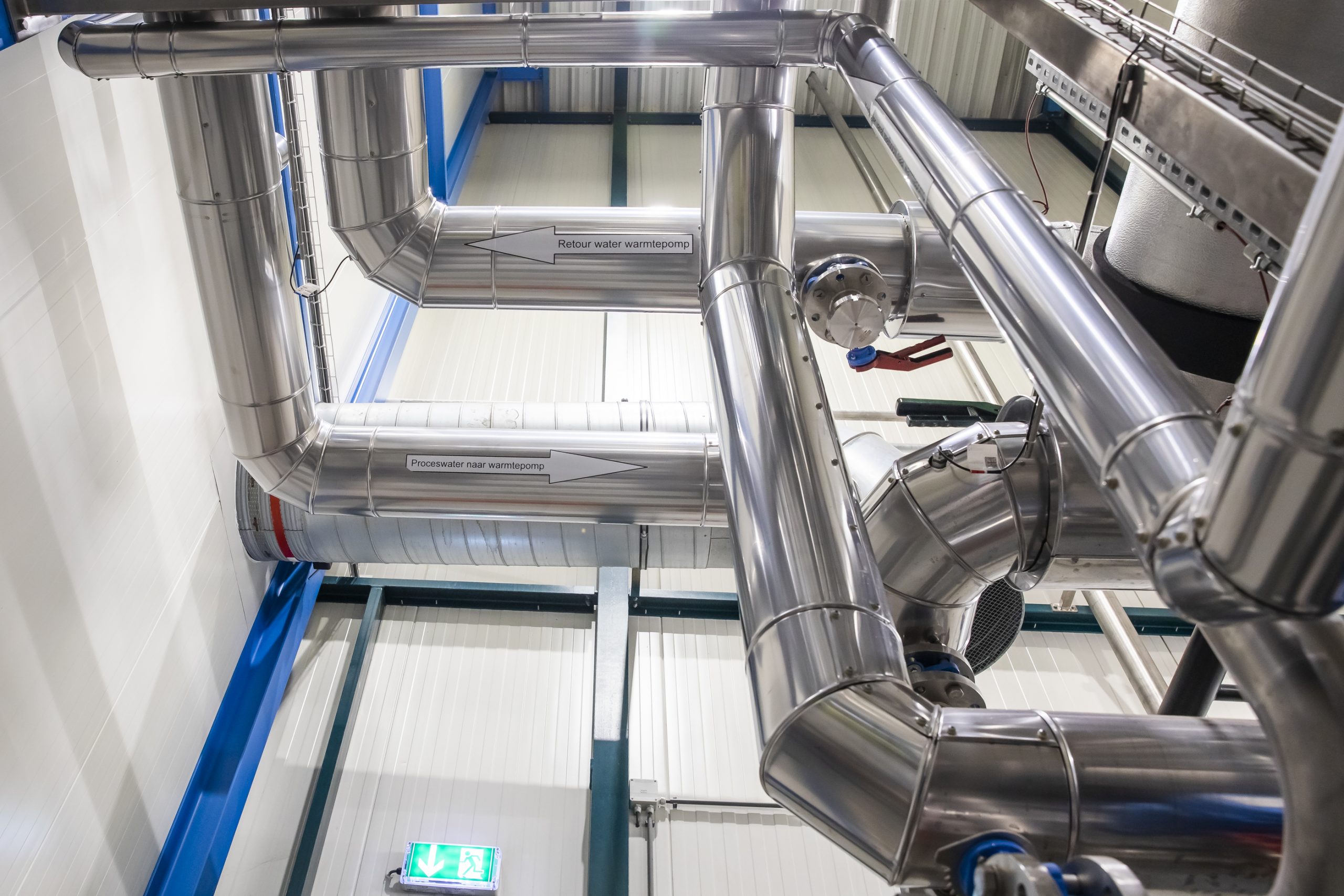

Use residual heat from machinery and processes

Cooling and freezing systems, warehouses or heating processes generate surplus heat that can be reused in other processes which require heating. The surplus heat can be recovered by using an industrial heat pump. Not only is it more sustainable, it can also save you tens of thousands of euros.

Reduce energy consumption? Use residual heat to meet your heating needs.

Request a free information brochureWhat is an industrial heat pump?

An industrial heat pump extracts heat from machines and processes and increases this surplus heat to a higher temperature of 80-90°C. As a result, heat that was previously lost can be used in industrial processes, for example to heat water, rooms or processes that require higher temperatures, such as blanching and pasteurization.

High COP

A heat pump requires only 25% of electrical energy to produce a temperature increase. With 1 part of electrical energy, it can therefore produce 4 parts of energy. Heat pumps therefore have a high Coefficient of Performance (COP): the ratio between the amount of energy supplied and the amount of energy used to drive the heat pump.

High-quality heat without gas

An industrial heat pump is the most efficient and sustainable way to make use of residual heat. It allows you to produce high-quality heat without using natural gas and this significantly reduces CO2 emissions. A heat pump also guarantees business continuity. Companies that still use gas to generate heat are not aware of these benefits, rising gas prices and uncertain gas availability. This makes an industrial heat pump essential for companies in the food processing industry.

Do you want to know how our heat pump works in practice every day? Then read the case study of the Zwanenberg Food Group. For this customer, we replaced a steam boiler with an industrial heat pump. This resulted in an energy saving of 95%. As a result, the heat pump paid for itself within 3 years through energy cost savings.

Customised industrial heat pump

The type of heat pump you choose depends, among other things, on the type of heat source (liquid flow or condensing), the type of delivery system (liquid, gas or boiling liquid) and the temperature increase required. This is why we always install an industrial heat pump on a customised basis. We look at the best way to integrate the heat pump into your business so that it pays for itself in the shortest possible time. One thing is certain, you will start saving on energy costs immediately after commissioning.

Benefits of an industrial heat pump

- Lower energy costs

- Reduced CO2 emissions

- More sustainable production

- Wide range of applications

- Generates heat without gas

- Intelligent reuse of residual heat

Industrial heat pump payback period

An investment in an industrial heat pump pays for itself quickly. The rule of thumb is that the more hours of operation, the faster the return on investment. The heat pump at our customer Zwanenberg Food Group paid for itself in 3 years through energy cost savings. The heat pump at Unilever also had a payback period of 3 years. We replaced the steam boiler with a heat pump, saving the company energy costs and making production more sustainable.

Ask about your savings potential

Do you also want to produce high-quality heat with an industrial heat pump? If so, we can perform an obligation free energy scan for you. This is a calculation of the possible energy savings with a heat pump in your company. The sooner you install a heat pump, the more you will save on energy costs.